SOLAR MOUNTING STRUCTURES

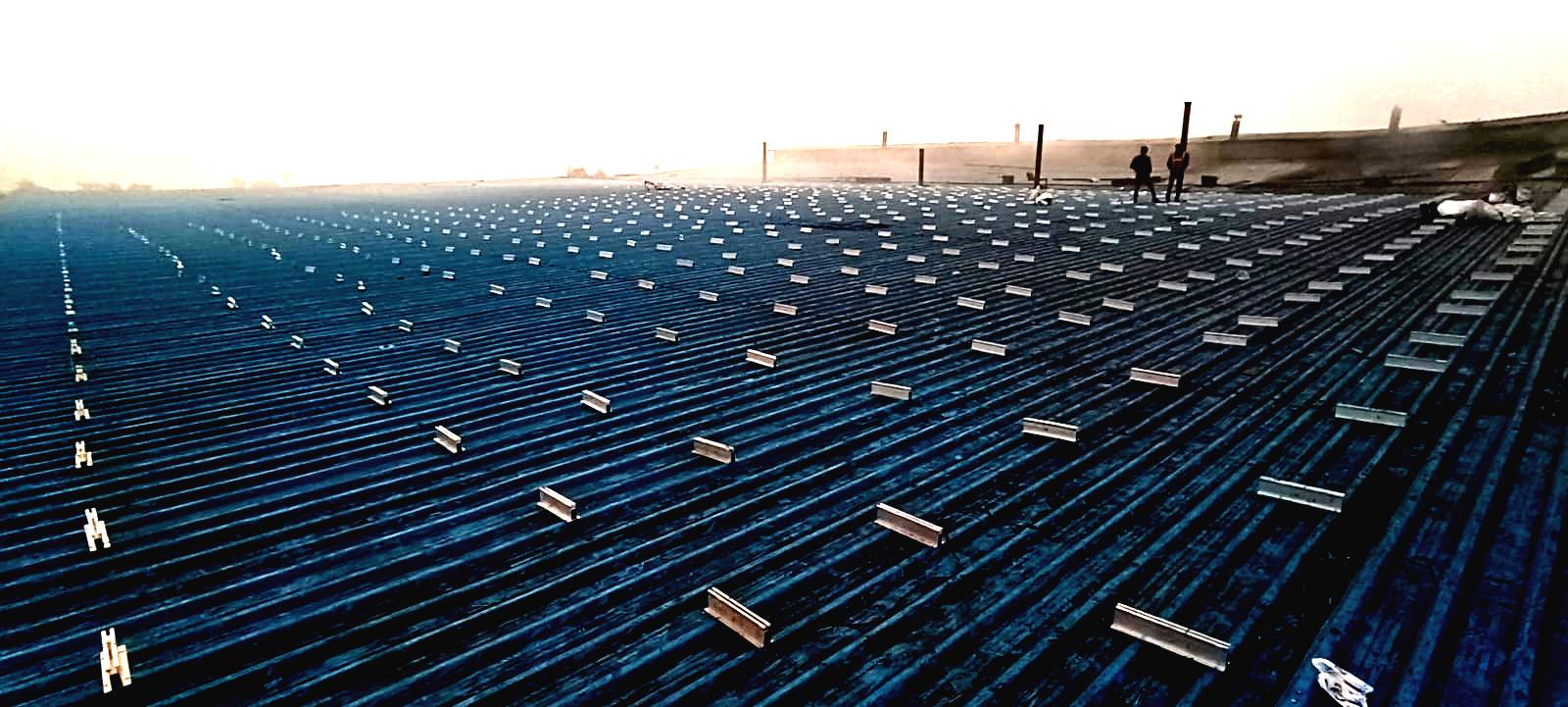

Normal Galvanized Structure

Super / Elevated Galvanized Structure

Aluminum mono/short rail structure

Depending on the exact requirements of the client, we will design the most efficient structure for them based on their specific requirements.

Normal structures are specifically designed for those clients who have open roof space that is unutilized and which they do not intend on utilizing in the near future as well. The front leg of this system has a length of around 500-700mm, while the back leg has a length of 1000-1200 mm, depending on the tilt angle, which is mostly between 15-20 degrees or according to the specific geographical location of the system.

Generally these structure can easily withstand a wind load of 180kmph or 50m/s.

Super structures or Elevated structures are specifically designed for those clients who have open roof space and they intend on utilizing the same roof in the near future as well. The front leg of this system has a length of around 2000mm, while the back leg has a length of 2800-3000 mm, depending on the tilt angle, which is mostly between 15-20 degrees or according to the specific geographical location of the system.

Depending on the exact requirements of the client, we will design the most efficient structure for them based on their specific requirements. Generally these structure can easily withstand a wind load of 180kmph or 50m/s.

Aluiminum structures are specifically designed for those clients who have a shed type metal sheet roof or cemented roof space. Unlike lengthy galvanized structures, Aluminum structures are generally light weight (as they intend to be installed on metal or cemented sheet) and are in the form of mono-rail or short-rail which then will be mounted on sheet with the help of u clamps and z clamps. Generally the tilt angle in this case will be between 3-6 degrees.

Depending on the exact requirements of the client, we will design the most efficient structure for them based on their specific requirements. Generally these structure can easily withstand a wind load of 180kmph or 50m/s.

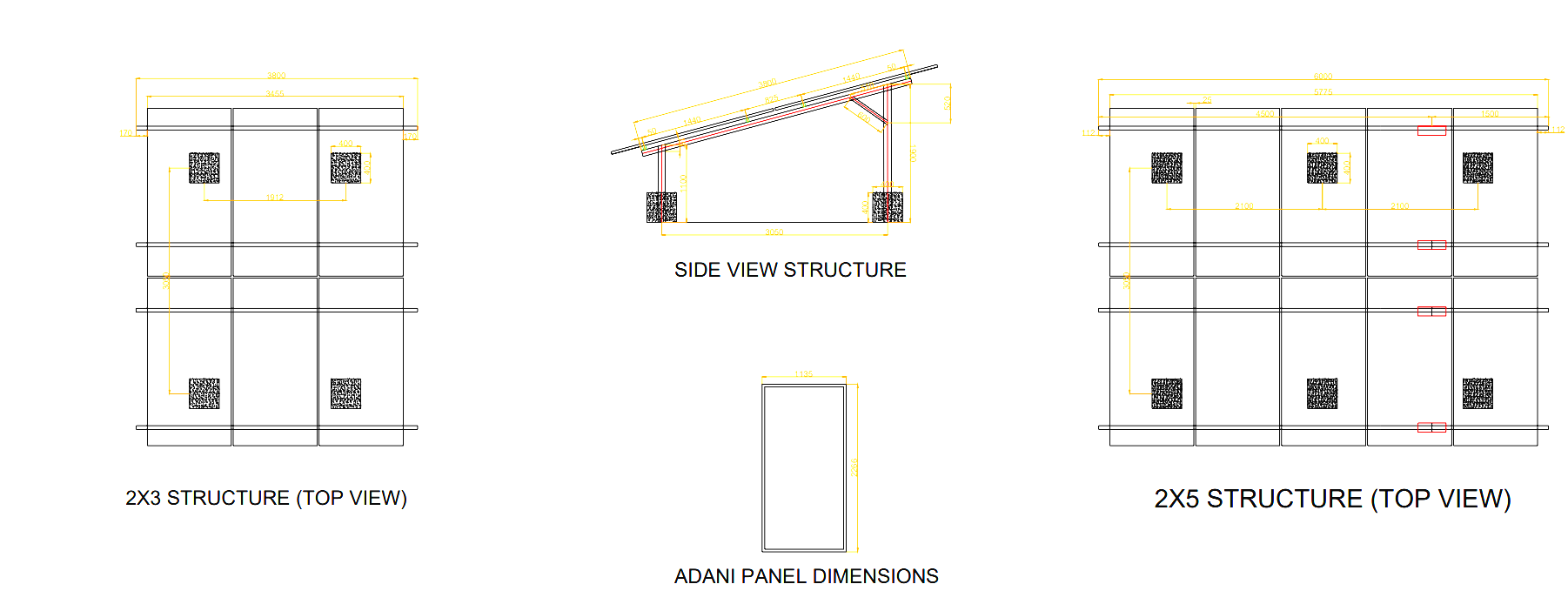

SOLAR STRUCTURE - 2D DESIGN

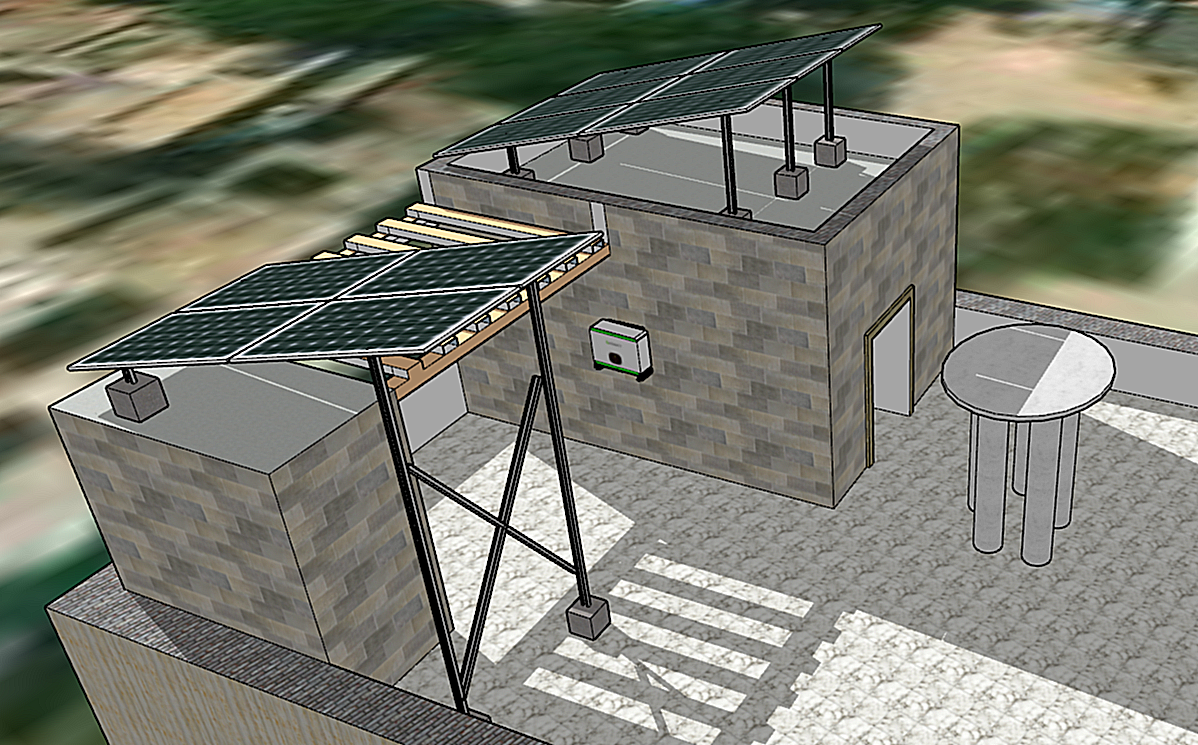

SOLAR STRUCTURE - 3D DESIGN

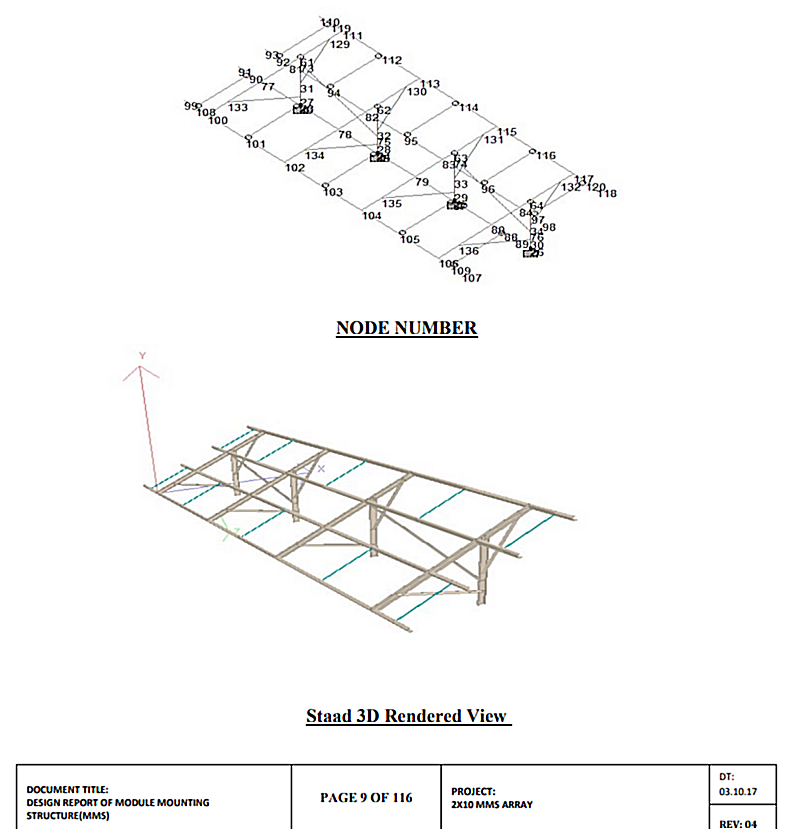

SOLAR STRUCTURE - STAAD REPORT

In order to provide our clients with an accurate idea of what we are going to provide, we use 2D design in order to get a better understanding of what is required of them.

We find that 2D designs can be very helpful in providing us with the exact dimensions that we will require to fabricate the entire solar structure in the most efficient way possible.

Our goal is to provide our clients with the best visual representation of the solar structure. To help them better understand the shadow analysis and the aesthetics of the roof once the solar mounting structure has been installed, we have designed 3D solar structure designs.

There have been a number of reasons why 3D designs can be very useful in a number of areas, for example, allowing us to collect data regarding shadow analysis, so that we are able to determine the gap that exists between any two rows of the solar mounting structure.

Our STAAD report provides us with an exact picture of the quality of material we have selected for wind loads, snow loads, dead loads, and self loads. This will help us determine what kind of material we should provide our clients.

Based on the analysis of this report, we design each and every solar structure as it gives a sense of reliability in the minds of our customers regarding the quality of the solar structure.